In-Mold Labeling (IML) System

DKM is the first injection molding machine company in China to research In Mold Labeling System technology, and has achieved many technological achievements in mold labeling systems so far. From high-speed injection molding machines, IML molds to in mold labeling robot systems, DKM has become the most comprehensive and technologically stable IML provider in China.

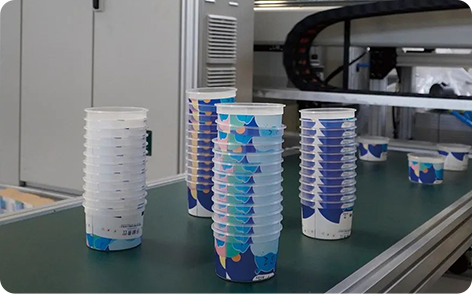

As the in mold labeling sytem innovator, DKM has a deep understanding of market demand and has introduced a highly efficient solution specifically designed for the production of thin-walled packaging, exemplified by its yogurt cup production line — a setup comprising DFS series injection molding machines paired with advanced IML (In-Mold Labeling) technology. This solution not only significantly enhances production efficiency but also ensures the high-quality standards of the final product.

High Precision

The DKM-DFS thin-wall high-speed machine features a high-precision single-cylinder injection system, combined with an independent hollow piston rod, ensuring the precision and stability of product dimensions and quality, making it suitable for high-speed injection.

High Speed

With low-inertia, high-precision injection technology, the machine reduces the inertia generated during injection, effectively shortening the cycle time and improving injection molding efficiency. The maximum injection speed can reach up to 800 mm/s.

Low Energy Consumption

Adopting low-inertia technology, the machine reduces energy consumption. The machine is equipped with an electricity meter, making energy savings clearly visible. It can save 20%-30% of electricity per machine. Optimized energy utilization efficiency reduces operating costs.

In Mold labeling injection Molding Machines Selection

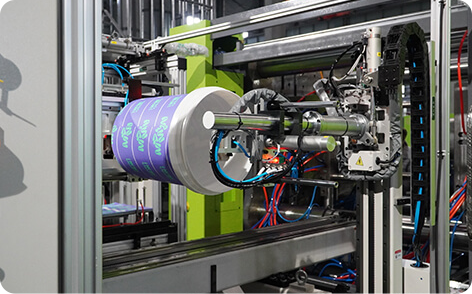

In Mold labelign system Technology

01 Basic requirement of labels

In terms of label quality, there is no peeling or fading that occurs with traditional labeling.It greatly enhances the label’s wear resistance, high-temperature resistance, and waterproof and moisture-proof properties, ensuring the integrity and aesthetics of the label in various environments.

02 In mold labeling cycle time

The IML molding cycle typically takes 3-6 seconds. Saving just one second in cycle time can increase production capacity by 30%-20%. Therefore, the cycle time plays a crucial role. Through continuous market satisfaction surveys, DKM actively analyzes and adopts feasible user feedback. Combined with mass production simulation tests before the shipment of the production line, DKM’s IML production line is characterized by its stability, speed, and precision.

DKM In mold labeling system- Standard Performance

Product

Milk Tea Cup

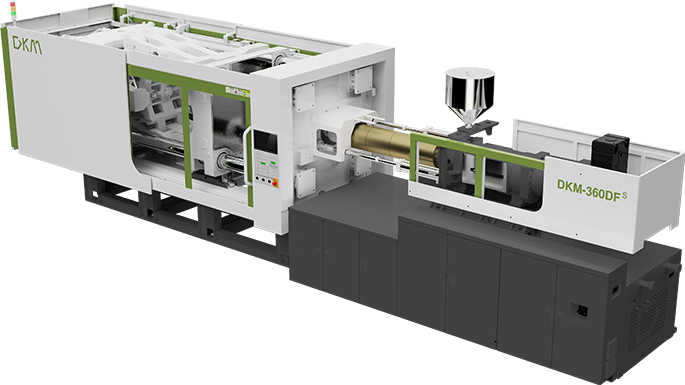

Machine

DKM-360DFS

Cycle Time

5.5s

Cavities

8

Product

Yogurt Box

Machine

DKM-310DFS

Cycle Time

5.8s

Cavities

6

Product

Paint Pail

Machine

DKM-460DFS

Cycle Time

18s

Cavities

1

IML Packaging Production Solution One-Stop Service

What DKM offers is not just high-quality production lines, but also a comprehensive service system that gives you peace of mind.

Pre-sales

Based on your production needs, we provide design solutions for the layout of water, electricity, and gas in the injection molding workshop.

During-sales

Before the shipment of the production line, we offer training for your employees on operation and maintenance. We also provide on-site installation services for the production line.

After-sales

We conduct regular on-site maintenance, customer visits, and gather user feedback. We have systematically planned service outlets both internationally and domestically to serve you efficiently.